Maxfil® – Maximized Alumina Trihydrate

Maxfil is a series of engineered alumina trihydrate (ATH) flame retardant fillers created for maximum filler loadings, extremely low viscosities, increased flame retardance and decreased formulation costs.

Using Maxfil MX100, MX104 or MX200 can achieve better glass wet-out, help reduce shrinkage and warpage, while also increasing the ability to achieve UL 94-VO, UL94 5VA and ASTM E84 Class 1 flame & smoke ratings.

MX100 MX104 MX200

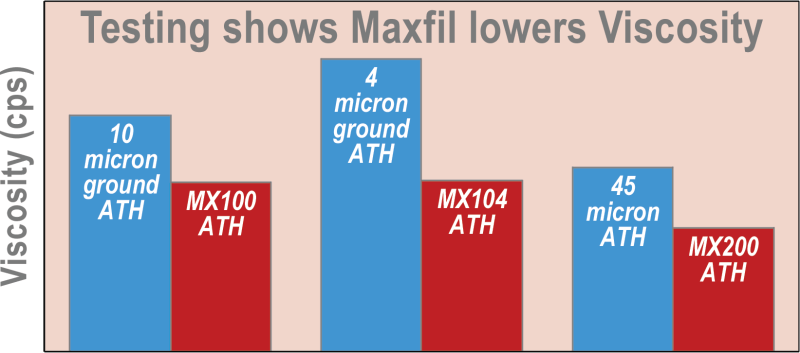

Testing shows MX100 results in a 28% decrease in viscosity over a 10 micron ground ATH. | Testing shows MX104 results in a 42% decrease in viscosity over a 4 micron ground ATH. | Testing shows MX200 results in a 32% decrease in viscosity over a 45 micron ATH. |