Prolite Microsphere Filler Blends

Prolite Blends feature solvent resistant expanded polymeric microspheres that can be blended with a variety of minerals and chemicals to your specific gravity requirements.

Prolite Microsphere Filler Blends extremely low density can replace other higher density raw materials thus reducing the weight of your product while increasing your volume and lowering your cost by volume. Reduced weight can mean better gas mileage, lower freight cost and easier product handling. In addition, the use of Prolite can reduce shrink, lower VOC’s, provide thermal insulation, and sound reducing properties. If you are already using a lightweight sphere, by moving to a lightweight blend you can reduce the number of separate additions to your batching, greatly simplifying your process and reducing potential for errors.

Prolite Microsphere Filler Blends can be used as a lightweight filler in many applications.

Paints ♦ Coatings ♦ Polyester Putty ♦ Caulks ♦ Sealants ♦ Foam Tooling Board

Under-body Coatings ♦ Fiberglass Spray-up ♦ Cultured Marble ♦ Concrete

Prolite Microsphere Filler Blends Benefits

The use of a Prolite Blend can provide considerable weight reduction. Due to its extremely low density, Prolite Blends will volumetrically displace other higher density fillers.

Lower Cost

The use of a Prolite Blend can result in significant cost savings. This is because Prolite Blends can volumetrically replace more expensive resins and binders.

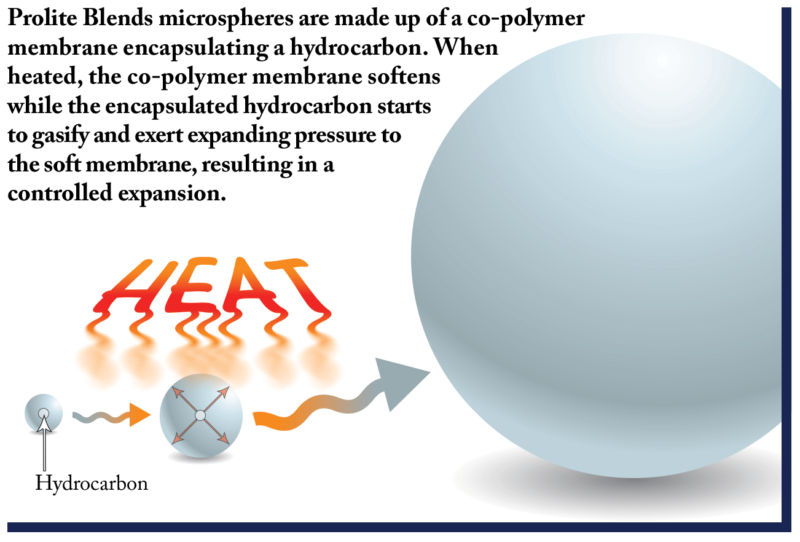

Closed Cell Structure

Prolite Blend expanded polymeric microspheres unique uniform closed cell structure will reduce water penetration and provide a more uniform foam product as compared to a blowing agent or open cell structure lightweight additive.

Sand-ability

Prolite Blend products have very low abrasiveness and are easy to sand.

Thermal Insulating

The use of Prolite Blends will reduce thermal conductivity of the final product. This is accomplished by its hollow, closed cell structure, which introduces closed voids into the material.

Sound Insulation

The use of a Prolite Blend in under-body coatings will give improved sound and vibration insulation properties.

Reduced Shrink

Prolite Blends have a low resin/binder demand. Adding Prolite Blends to a matrix with a shrinking resin/binder can result in less shrink, improving the properties and finish of the end product.

Reduce VOC’s

The use of Prolite Blends will volumetrically reduce resin/binder which reduces VOC emissions from the resin/binder.